Nowadays, colour matching is only carried out visually in a few companies. Measurement with a laboratory device is much more objective and reliable and can be easily integrated into existing QM structures thanks to digital data acquisition.

Nowadays, colour matching is only carried out visually in a few companies. Measurement with a laboratory device is much more objective and reliable and can be easily integrated into existing QM structures thanks to digital data acquisition.

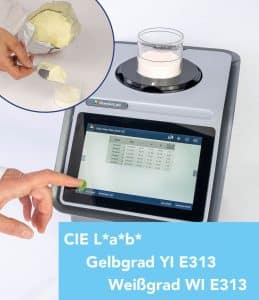

With HunterLab’s Agera, highly accurate and repeatable measurements can be made, displayed and compared with the desired colour scales and indices. Differences are clearly displayed and the software immediately indicates when defined tolerances are exceeded. Views such as spectral diagrams or 2D colour diagrams also allow a quick visual assessment of the measured colour values. When measuring milk and whey powder, the CIE Lab scale together with the degree of yellowness YI E313 and possibly the degree of whiteness WI E313 are meaningful.

A measurement is easy to carry out by filling the powder into a glass cuvette, positioning it on the measuring aperture and triggering the measuring flash with a simple push of a button. With the appropriate setting, a photo of the measuring surface as “seen” from below by the sensor can be taken and saved for documentation purposes.

A measurement is easy to carry out by filling the powder into a glass cuvette, positioning it on the measuring aperture and triggering the measuring flash with a simple push of a button. With the appropriate setting, a photo of the measuring surface as “seen” from below by the sensor can be taken and saved for documentation purposes.

The measurement data is either stored in the device via the EasyMatch Essentials firmware and can be easily exported if required, or the device can be connected to a PC and the EasyMatchQC software used, which enables the data to be displayed and analyzed more clearly. The simple ASCII export, for example, is a practical tool for quality control in particular.

Regardless of the application for which you produce milk and whey powder – with the Agera from HunterLab, the production process can be ideally monitored and accompanied by colorimetry. This gives your customers and buyers a consistent product in terms of colour, they develop confidence in the quality of your products and remain loyal to you.